- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

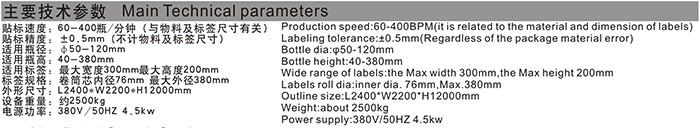

Rotary labeling machine, suitable for industries such as alcohol, food, beverages, pharmaceuticals, and daily chemical products.

It can achieve labeling of various bottle shapes such as square, flat, circular, conical, double conical, upper cone and lower circular, elliptical, etc., and has multiple labeling methods including single-sided labeling, double-sided labeling, front and back and neck labeling, conical bottle labeling, square bottle labeling with three or four sided labeling, etc.

Mechanical positioning can be achieved by slotting at the bottom and sides of the bottle, or by servo positioning of the bottle logo or mold line through visual sensors, with high accuracy,

Specially designed for high-end products produced by customers.

The marking station adopts a highly sensitive German Lauyi marking paper sensor with high-precision servo motor control for marking.

Adopting spiral bottle separation and star wheel guide plate bottle feeding method, ensuring accurate delivery of bottles to the center position of the bottle holder and precise symmetry of labeling.

The labeling station adopts a completely different method from linear labeling machines, with eight directional adjustment and dual pressure roller feeding to ensure active tension of the labels and stable labeling at high speeds.

The device can be equipped with multiple labeling mechanisms to ensure labeling accuracy and quality, and transparent labels are bubble free.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号