- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

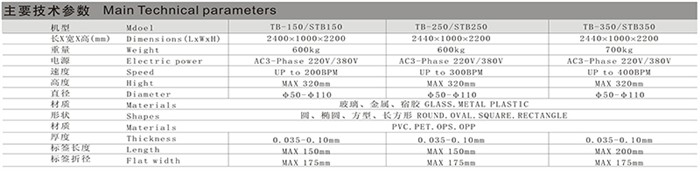

Equipment features:

1. The whole machine is made of stainless steel and high-quality aluminum alloy, with a reasonable, compact structure and easy adjustment;

2. No need for anchor bolts, it can be easily moved and flexibly matched with the production site;

3. Shrink film label holder, easy to adjust according to different label paper tubes ranging from 5 "to 10";

4. No tools required, the transmission mechanism can be easily adjusted and suitable for different bottle types;

5. The labeling method is unique, using a compression labeling method that is both convenient and reasonable;

6. Label cutting detection system to ensure the lowest error;

7. The uniquely designed cutter head, within the specified range, can be replaced without changing the cutter holder, making tool changes fast and convenient;

8. The center column clamping system allows for quick replacement without the need for any tools;

9. The bottle dividing screw, positioning belt, and conveyor chain adopt synchronous adjustment method, making speed adjustment simple and fast;

10. Using Japanese servo motors and high-sensitivity optoelectronics, the cutting length is precise.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号