- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

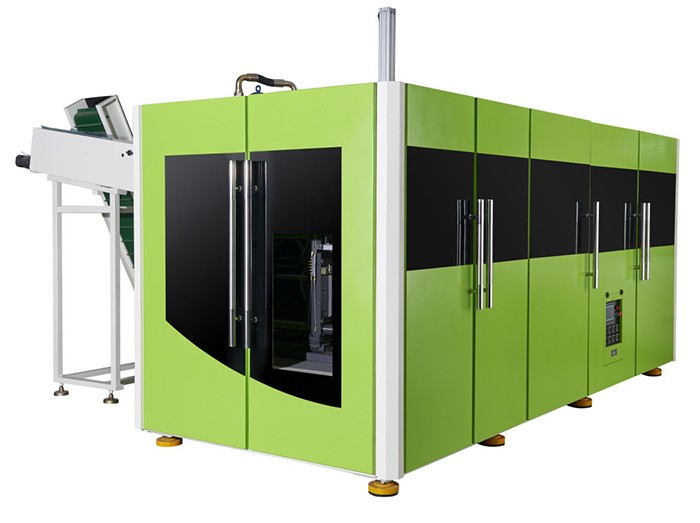

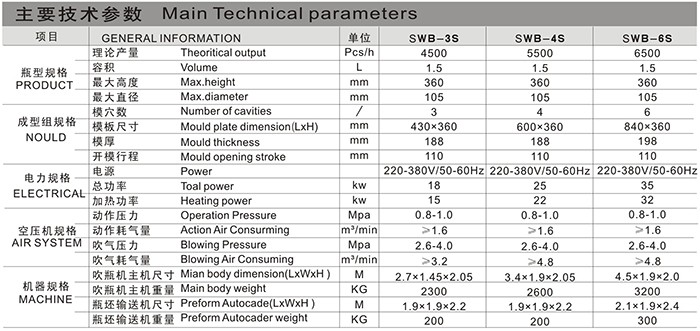

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

characteristic:

1、 This machine adopts a human-machine interface to control all working programs, including automatic loading, automatic blowing, and automatic bottle discharge. All action cylinders are equipped with magnetic induction switches, and connected to PLC to control the entire program to detect each action cylinder. When the stroke is in place, the next action will work, and when the stroke is not in place, the next action will automatically protect and alarm. The PLC displays the fault location.

2、 The machine has fast movement speed, accurate positioning, and smooth movement.

3、 According to the requirements of the model, a cross hyperbolic arm is used for boosting and locking the mold, with strong locking force. The opening and closing stroke of the mold can be adjusted according to the size of the product, reducing the opening and closing time.

4、 The far-infrared heating tube has strong penetration and uniform heating of the preform by rotation. The heating temperature of each group is controlled separately by PLC or electronic regulator.

5、 Featuring a unique oven design, the bottles are tightly spaced during heating, and the spacing is adjusted according to the size during blowing, shortening the drying passage and reducing energy consumption.

6、 The gas path design is divided into three parts: micro blowing, high-pressure blowing, and low-pressure action, to meet the gas source requirements for blowing different products.

7、 The automatic oiling device provides better protection for the machine. The production process is fully automated, the product quality is good, the bottle body is not contaminated, it has the advantages of low investment, high efficiency, convenient and safe operation, and simple maintenance.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号