- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

ProductsHome>Products

Lp series fully automatic rotary bottle sorting machine

Time:

2024/11/22 17:06:07

popularity:4761

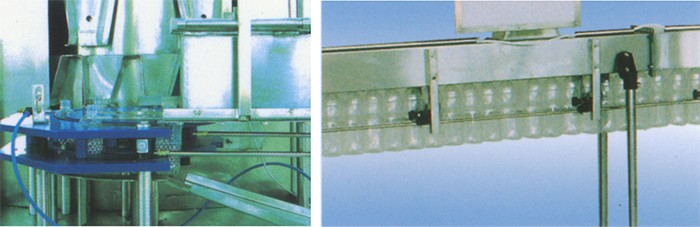

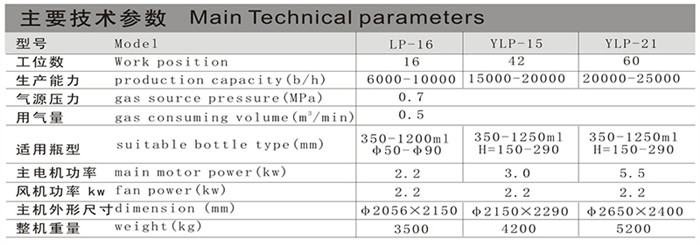

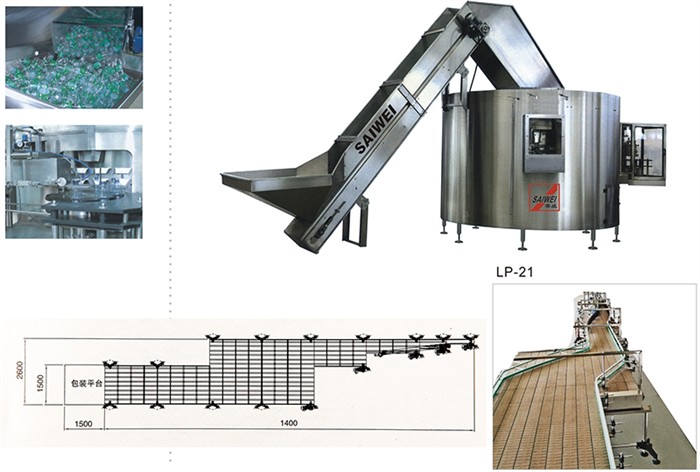

The fully automatic rotary bottle sorting machine has introduced advanced international technology and is specially designed as a supporting equipment for the flushing, canning, and capping three in one machine. The disorderly empty bottles are sorted in an orderly manner by the bottle sorting machine, and the qualified bottles are transported to the three in one machine at high speed, high efficiency, and hygiene through the wind conveyor at the bottle hanging mouth to meet the needs of high-speed filling. In order to improve the production efficiency of the entire line, the wind conveyor has been improved and designed to meet the production requirements of aseptic canning.

QR code

Contact Us

Address: No. 88, Baixiong Road, Sanxing, Jinfeng Town, Zhangjiagang City, Jiangsu Province, China

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号