- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

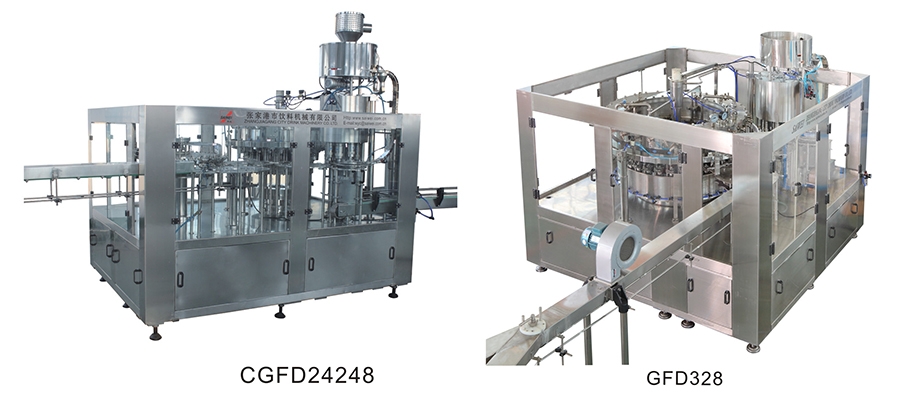

The CGFD series of bottle flushing, filling, and capping units have introduced advanced gas filling technology from abroad, making it an efficient fully automatic liquid packaging equipment.

This machine is suitable for packaging carbonated beverages and has the following characteristics: the filling cylinder, filling valve, and other components that come into direct contact with the material are made of high-quality stainless steel or non-toxic materials, which meet food hygiene requirements; The sealing element is made of heat-resistant rubber, which meets the process requirements of high-temperature disinfection for users; The PLC programmable controller is used to achieve fully automatic control from bottle feeding to packaging completion. The variable frequency speed control is adopted, which is easy for users to adjust and prepare, meeting the production capacity requirements of different processes; The principle of equal pressure filling and spring valve are adopted to ensure the quality of the beverage. An advanced magnetic clutch adjustment cap torque device is used to ensure the quality of the cap.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号