- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

Purpose and Characteristics

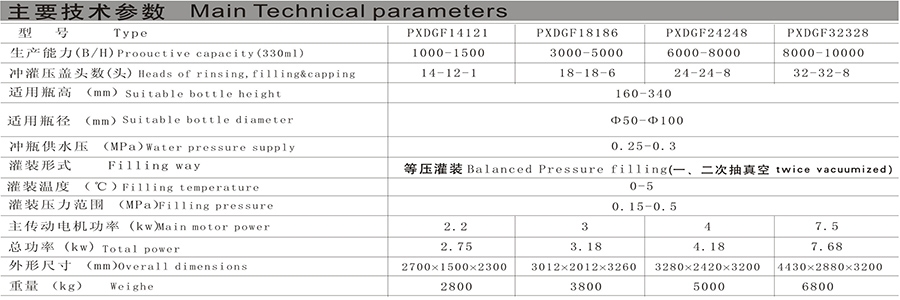

The GDY series beer filling unit is suitable for filling fresh beer in round and irregular cans. The unit consists of a soaking bottle machine, an external bottle brushing machine, an internal bottle brushing machine, a bottle washing machine, a filling and capping machine, and a conveyor. The characteristics of this filling machine are: it adopts pre vacuum filling C0 filling to reduce the content of dissolved oxygen, and the beer filling valve designed according to the principle of equal pressure filling is stable, non foaming, and has low loss of liquor. The bottle cap undergoes secondary sterilization during the cap delivery process to reduce bacterial flora. The two machines for filling and sealing are integrated, with infinitely variable transmission and adjustable filling capacity. The transmission is smooth and easy to maintain.

Our company can provide semi-automatic and automatic cleaning, filling, and capping equipment for single machines and complete sets, as well as unique filling processes. It is the preferred equipment for beer and beverage manufacturers to produce multiple varieties in bulk

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号