- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

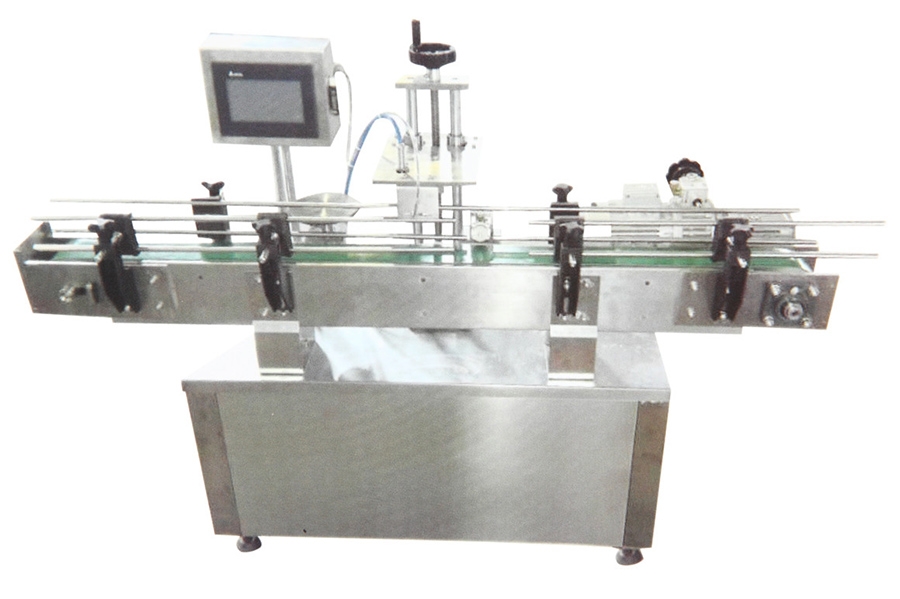

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

The basic principle of our company's vacuum detection machine is that if the vacuum degree inside the can (bottle) is different, the deformation of the can (bottle) lid will also be different. This machine uses precision components to detect, and the data is processed by the computer to automatically analyze whether the product meets the required vacuum degree. Products that do not reach the vacuum degree are immediately pushed out of the conveyor line by the cylinder behind. Therefore, this equipment can perform dynamic online detection on the conveyor belt and automatically remove cans (bottles) that have not reached the set "vacuum" or "internal pressure" after detection. This machine is suitable for two-piece aluminum cans, three piece iron cans, glass bottles, and all other laminated containers, with simple and efficient operation. Its key components are made of German and Japanese products, which is the first and only high-tech product in China to replace imports.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号