- Gas filled beve...

- Juice beverage ...

- PET bottled wat...

- Five gallon bar...

- Glass bottle fi...

- Can filling lin...

- Water treatment...

- Juice beverage ...

- Concentrated ju...

- Protein beverag...

- Whole plant con...

- Automatic bottl...

- Bottle blowing ...

- LABELLER

- labeller

- Membrane packag...

- Spray coding ma...

- case packer

- palletizer

- Winding machine

- Carbon dioxide ...

- Liquid nitrogen...

- Related standal...

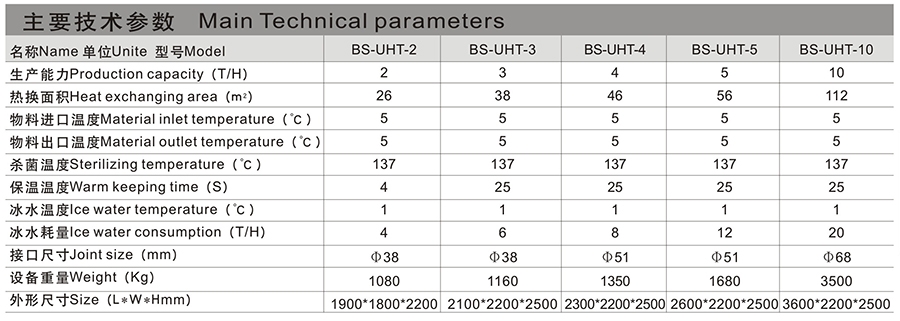

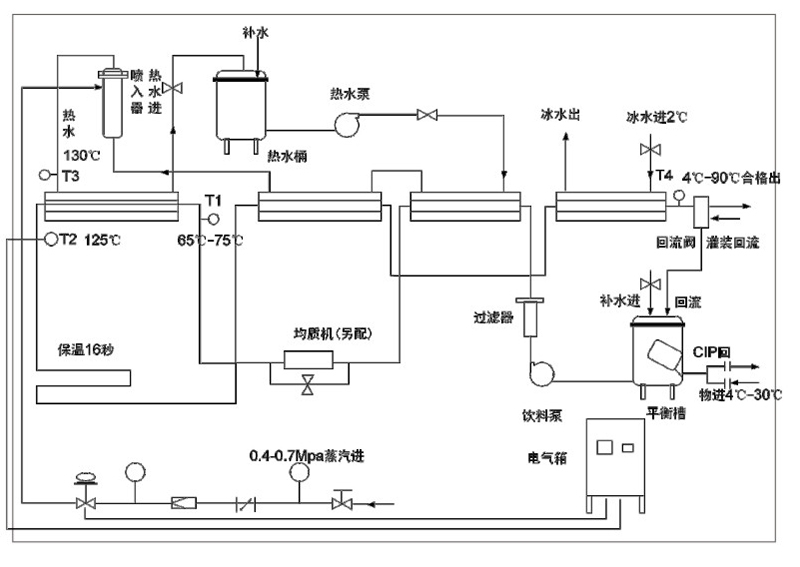

The plate type ultra-high temperature instantaneous sterilization system is intelligent PLC automatic control, with a production capacity of 3-10 tons/hour to choose from. In response to the process requirements for low-temperature, medium temperature, high-temperature, and hot filling of beverages, the system divides the plate working section into a sterile working section and a general working section. A seven stage heat exchange unit process design is selected to effectively utilize heat sources and minimize energy consumption. The perfect CIP and SIP system design meets the cleaning and sterilization requirements of production equipment. The sterilization, heating, and filling outlet temperature adjustment of materials use superheated water as the medium, with high temperature control accuracy.

This automatic plate type ultra-high temperature instantaneous sterilization system uses world-renowned manufacturers ALFA and LAVAL for its key components APV. SPIRAX. SARCO. SIEMENS. FESTO and other products.

Chairman and General Manager: Zhang Xiufeng

Phone:0512-58570998 Fax:0512-58578889

Hotline:0512- 58530889

mobile phone:13901565836 13806229377 E-mail:wyc@saiwei.com.cn

website:www.saiwei.com.cn 苏ICP备2024137681号